RDU: Radpid Deployment Unit

Our RDUs are highly portable and can be deployed and installed easily. Consisting of a base frame which is composed of high quality steel galvanized beams and ballast, offers movement and dismantling of the site elements in a simple and fast way and fast erection of telecommunication towers without the need of major foundation and civil works

RDUs are the most effective solution to solve problems associated with civil works, such as excavation, concreting, back filling , template setting, curing and involves time and quality issues. It offers the greatest transmission capacity possible in high-mobility units during possible downtime of fixed network or as a base station in sites with infrastructural limitations.

Jhamuna Tower Tech designed a Rapid deployment tower of 35m height. The tower is triangular in plan and can safely withstand a wind velocity of 160kmph. The tower has to be installed on a fast track basis and after few years, it has to be dismantled and reused elsewhere. Hence

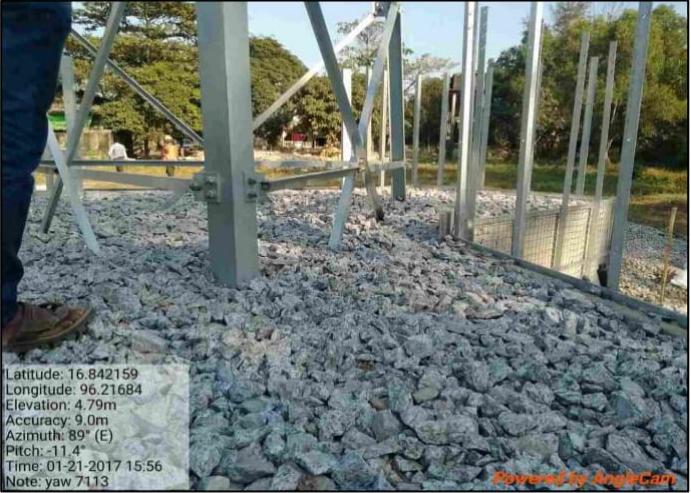

the tower base is not anchored to ground and it is fixed to a steel base frame spread over a specific area and is held down by counter weight to resist the forces from the tower due to wind and antenna loads. A stub of 0.85m height is provided which is welded to a base plate

The design of the tower is based on ANSI/TIA- 222-G. The detailed engineering is available in house for various wind speeds and terrain categories

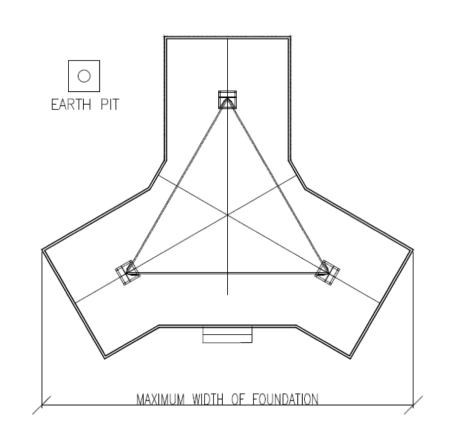

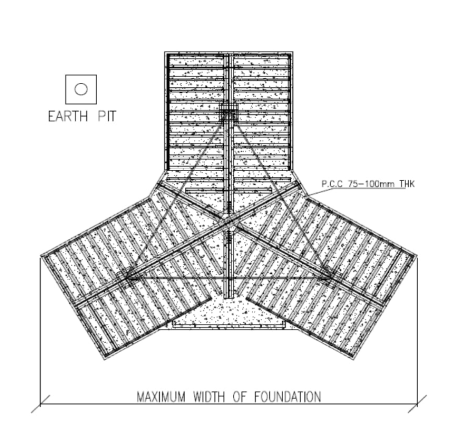

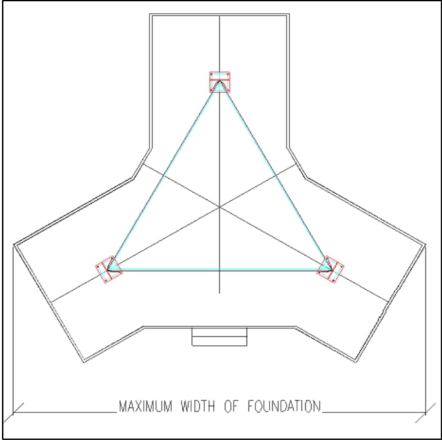

A trapezoidal shape of frame is chosen for supporting the tower as shown in the figure below. The basic requirement which should be satisfied is that the centre of gravity (c.g) of the frame and the c.g of the tower base should be same. This means that there will not be any eccentricity in transfer of

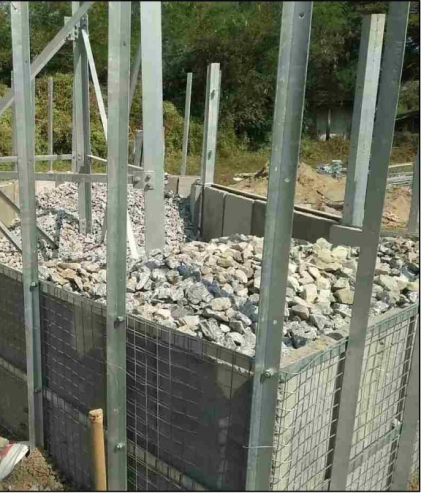

force from the tower to the supporting frame. After doing PCC for a depth of 100mm welded mesh is spread across the trapezoidal area. Then the frame

is assembled and bolted with the stub. The fencing posts along with the chain linked fencing are erected for a depth of a particular depth. It is then filled with ballast for the required depth. Then the tower is assembled and erected

It is proposed to fix the tower on a base frame, which shall support counter weights to resist the over turning moment from the tower. The tower leg is extended and welded to a base plate, which is fixed to a steel frame using equal angle built up sections, spread over an area. The extended portion is filled up using coarse aggregate, which will act as counter weight. To retain the ballast fencing posts fixed with the base frame connected at different levels for stability is covered with cement tiles. The top of ballast is leveled with a 75 to 100mm of concrete for fixing other equipments such as DG, ODBTS, etc. These weights are also included in the design check of foundation